Commercial steel, often referred to as mild steel or carbon steel, is a widely used building material known for its versatility, strength, and cost-effectiveness. It is primarily composed of iron and carbon, with small amounts of other elements such as manganese, sulfur, phosphorus, and silicon.

One of the key advantages of commercial steel is its ability to be easily formed into various shapes and sizes, making it suitable for a wide range of construction applications. Whether it’s beams, columns, channels, or plates, commercial steel can be fabricated to meet the specific needs of almost any project.

Additionally, commercial steel offers excellent structural integrity, making it ideal for supporting heavy loads and withstanding external forces such as wind and earthquakes. Its durability ensures longevity, reducing the need for frequent maintenance and replacement.

Let’s delve into those specific types of steel:

- Steel Angles: Steel angles, also known as angle iron or L-shaped steel, are structural steel products characterized by their L-shaped cross-section. They are formed by bending a piece of steel at a 90-degree angle. Steel angles are commonly used for bracing, framing, support structures, and as reinforcements in construction projects. They come in various sizes and thicknesses to suit different applications.

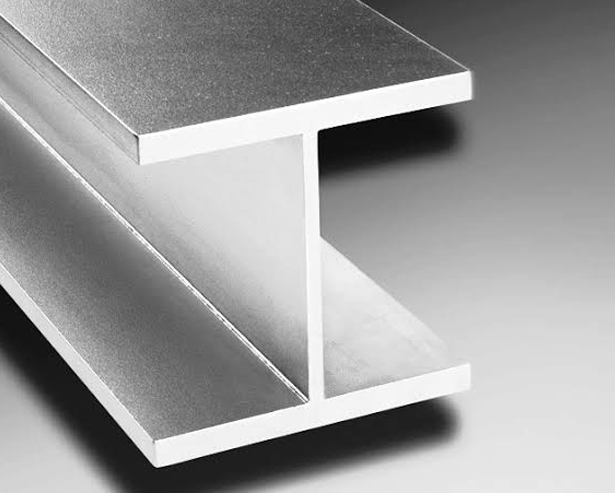

- H Beams (H-Sections): H beams, also known as H-sections or universal beams, are structural steel beams with an H-shaped cross-section. They are characterized by their wide flanges and web, which provide excellent load-bearing capacity and structural stability. H beams are commonly used in building construction, bridges, and infrastructure projects to support heavy loads over long spans. They come in various sizes and weights, allowing engineers to choose the most suitable beam for the specific requirements of the project.

- Steel Bars: Steel bars are long, solid metal bars with a circular, square, rectangular, or hexagonal cross-section. They are produced by casting, rolling, or extrusion processes and are available in various grades and sizes. Steel bars are versatile structural elements used in construction, manufacturing, and engineering applications. Common types of steel bars include round bars, square bars, flat bars, and hexagonal bars. They are used for reinforcement, fabrication, machining, and forming operations, depending on their specific properties and applications.

- Carbon Steel: The most basic type, primarily composed of iron and carbon. It’s versatile and used in various applications due to its strength and affordability.

- Alloy Steel: Enhanced with additional elements like manganese, chromium, nickel, or molybdenum to improve specific properties such as strength, hardness, and corrosion resistance.

- Stainless Steel: Known for its corrosion resistance due to the presence of chromium. It’s often used in environments where corrosion is a concern, such as in food processing, chemical plants, and marine applications.

- Tool Steel: Designed for making tools and dies due to its hardness, resistance to abrasion, and ability to hold a cutting edge. It’s used in machining, stamping, and forming operations.

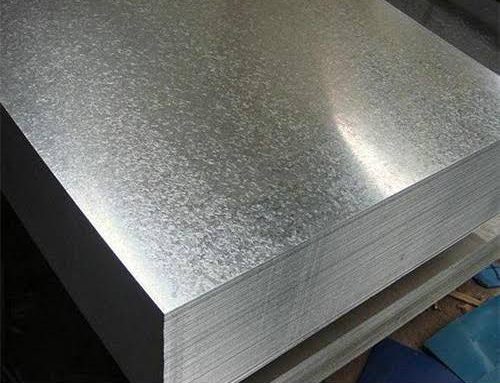

- Galvanized Steel: Carbon steel coated with a layer of zinc to protect against corrosion. It’s commonly used in outdoor structures, fencing, and automotive parts.

- Mild Steel: Also known as low carbon steel, it’s easy to work with and suitable for welding, bending, and forming. Widely used in construction, automotive, and manufacturing industries for its versatility and cost-effectiveness.